Dominion Automation commissions a complete line of sturdy, accurate fillers for controlled dispensing of products unsuitable for traditional auger filling. The line consists of single/multiple vibrating trays that carefully regulate product into a loadcell-equipped weigh bucket. When required weight is attained, bucket empties into container. Models available for single cycle, as well as fully automatic, multiple position systems with conveyors, container handling, and checkweigher feedback for verified accuracy and package weight.

FILLERS & CAPPERS

Monobloc Fillers

With a multitude of distinct machine series, Filler Specialties has the monobloc pressure gravity filling and capping machine that’s best for your application.

Standalone Cappers

Models range from six valve to 72 valve machines for speeds from 10 containers per minute to 700 containers per minute.

Systems & Custom Fillers/Cappers

Tailored for the end user’s current needs with room to grow, Filler Specialties has the right container filling and packaging equipment for your application.

AUGER FILLERS

MODEL B/350E

The innovative design makes the Model B-350e an affordable, reliable auger filler with the same rugged construction and dependable service which All-Fill is renowned for. It is the ultimate in operator convenience – precision engineered for time saving, cost cutting performance.

MODEL B/600

The Model B-600 Auger Filling Machine was designed for our customers who prefer Allen Bradley PLC controls. The innovative design and PLC-based controls make it a powerful, reliable, auger filler with rugged construction and dependable service which All-Fill is renowned for.

MODEL CF

The Model CF Auger Filler is a bench top unit designed for dosing of all types of powders including pharmaceuticals and chemicals for a weight range of milligrams to ounces. All product contact parts are made of Stainless Steel and are designed for easy changeover and clean up.

MODEL DHA

The Model DHA is a complete, economical solution to your filling production requirements. It consists of the industry-proven All Fill filling heads and conveyor mounted on a sturdy frame.

MODEL SHA

The Model SHA: Single Head Automatic Auger Filler is a complete, economical solution to your filling production line requirements. PLC control system provides precise selection and adjustment of fill amounts and machine functioning.

MODEL TAA

All-Fill Model TA Twin Auger Fillers are designed for high speed/high volume dispensing typically encountered in vertical form-fill-seal, cup filling, or other applications requiring dual position filling.

MODEL B/S

Our Model BS Pouch Filling System fills small pouches with product. This is a “bulk and dribble” application.

MODEL BS BOX FILLING SYSTEM

The Model BS Box Filling System fills large boxes with product. This is a “bulk and dribble” application. When the empty box is in place, a tare weight is established. A pneumatic lift then lifts the empty box from the scale to its bulk-fill position. A bottom-up fill occurs, ensuring that the amount of dust caused by product in motion will be minimized.

Multiple Auger Fillers

All-Fill’s multiple spindle auger systems provide controlled, multiple auger dispensing of product across production lines using cup machines, form-fill-seal equipment, thermoformers, and strip/pouch machines.

High Speed Rotary

All-Fill’s line of high speed automatic rotary fillers provides high throughput and speeds for even the most demanding production environments. Rotary auger filling systems operate continuously with product dispensed into funnels traveling on a circular, multi-position turret.

VIBRATORY FILLERS

E/Series

The E/Series of vibratory feeder is the logical solution in taking scoop and scale companies to the next level. Our economical linear net-weigher provides precise feeding and weighing of free-flowing and occasionally non free-flowing products.

ST/Series

The ST/Series of vibratory feeders is the filling solution for the precise feeding and weighing of free-flowing and occasionally non free-flowing products. Vibratory fillers are able to move and fill products such as snack foods, hardware, and more without causing damage to the product.

PN/Series

The PN/Series of vibratory feeders is the pneumatically operated general purpose feeder that is specifically designed for the controlled feeding and weighing of free-flow products.

HX/Series

The HX/Series is expertly designed for the feeding of free-flowing products into cases or drums ranging in weights of 5 to 75 lbs. Free-flowing products like nuts, seeds, spices or snack foods, and more can be fed, weighed, and dispensed at accuracies of ± 0.25 to 1%.

GF/Series

All-Fill’s gross filling vibratory feeder is designed for the accurate bulk feeding, weighing, and dispensing of 5 to 100 lbs. of free-flowing products such as pretzels, aggregate, and candies while using the bag, box, or rigid container. The GF/Series is capable of filling at speeds of up to 10 containers per minute with accuracies of ±0.25 to 1%.

HT/Series

All-Fill’s High Precision net weigh filler is design to fill high valued products, such as pharmaceuticals, cannabis, and precious metals with weighing accuracy’s of .01g. Custom designed for each application using small, light-weight buckets or tipping platforms, the product is dispensed with V-style pans for precision.

CUP FILLERS

SC/Series

The SC/Series cup filler can accurately dispense free-flow products such as rice, popcorn, pecans, seeds, candy and more. Fill weights from .25oz to 15lbs can be achieved at speeds up to 120 per minute. Easily removable volume cups and servo position control are standard features on this line.

CM/Series

The CM/Series cup filler has been expertly designed to accurately dispense free-flow products such as peanuts, snacks, rice, candies and spices. Weights from .25oz to 3lbs can be automatically and continuously filled into containers as they pass under the dispensing plate.

PF/Series

The PF/Series cup filler is designed to fill uniformed products such as paint balls, pretzel nuggets, and candy by count. Individual pockets for each item are machined into a delrin plate and indexed via a servo motor for the correct count. Fill counts as low as 1 can be achieved.

PR/Series

The PR/Series volumetric filler is designed to fill chewing tobacco, or synthetic chewing tobacco into tins at high rates of speed. A volumetric plate is filled with product and gently scraped/pushed into the container.

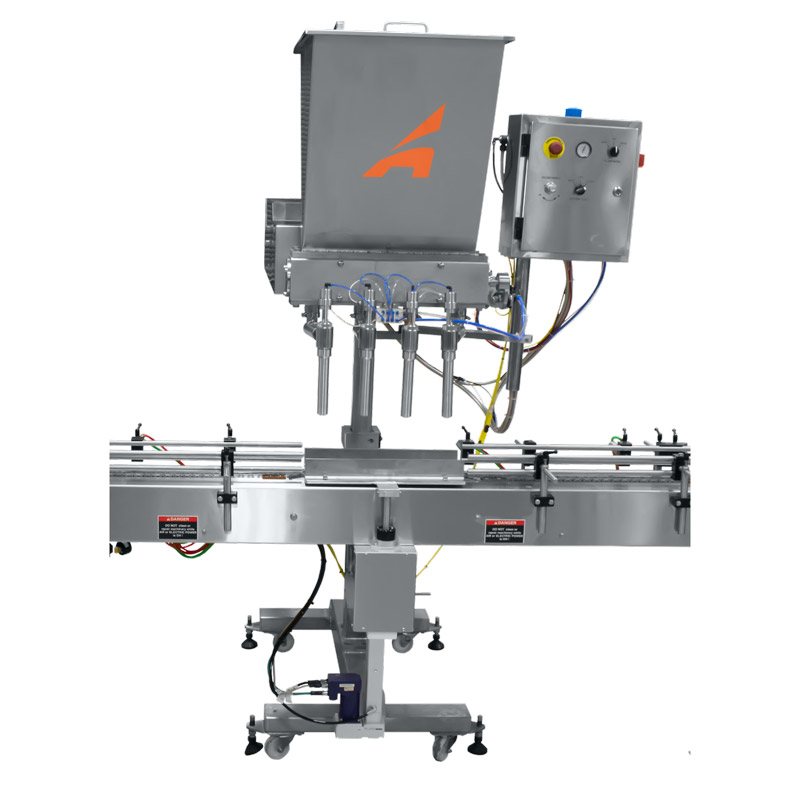

PISTON FILLERS

Model 205

A compact, single nozzle, semi-automatic piston liquid filler for liquids, creams, pastes, and other viscous products dispensed in smaller capacity applications. Volumes dispensed can range from 5 to 50 ml (up to 1.69 fl. oz.) per cycle. Compact size makes the Model 205 ideal for tabletop/benchtop operations for filling cosmetic and pharmaceutical products into tubes, pouches, and other small containers.

Model 305

The Model 305 is a versatile single head piston liquid filler for liquids, creams, pastes and other viscous products. Fill volumes can range from .25 oz to 87 oz per cycle with up to 60 fills per minute in either manual or automatic operation.

Model 505

Liquids, creams, pastes, and other viscous products can be dispensed using All-Fill’s line of volumetric piston fillers. Models are available to dispense product in amounts ranging from less than an ounce to over a gallon per cycle.

Series 500

The Series 500 is a line of heavy duty, pneumatically operated, high capacity volumetric piston fillers for a wide range of liquids, creams, pastes, and gels. Our Piston Fillers can dispense particulates up to 7/8” diameter at production volumes of 8 oz. to 1 gallon per fill.

Series 1500

The 500 Series Volumetric Piston Filling Systems are designed for the completely automatic, multiple position, in-line dispensing of liquids and pastes in volumes to match specific production requirements. Precision bored, heavy-walled metering cylinders dispense product at accuracies of ±0.25%.